Burning Purg Gases from Biogas Upgrading

Biogas from agricultural fermenters or from landfills can be purified and upgraded by separating CO2 and eventually nitrogen so that it can be fed into the natural gas grid or used as liquified methane as a fuel. With this natural gas can be replaced and CO2 emissions can be reduced.

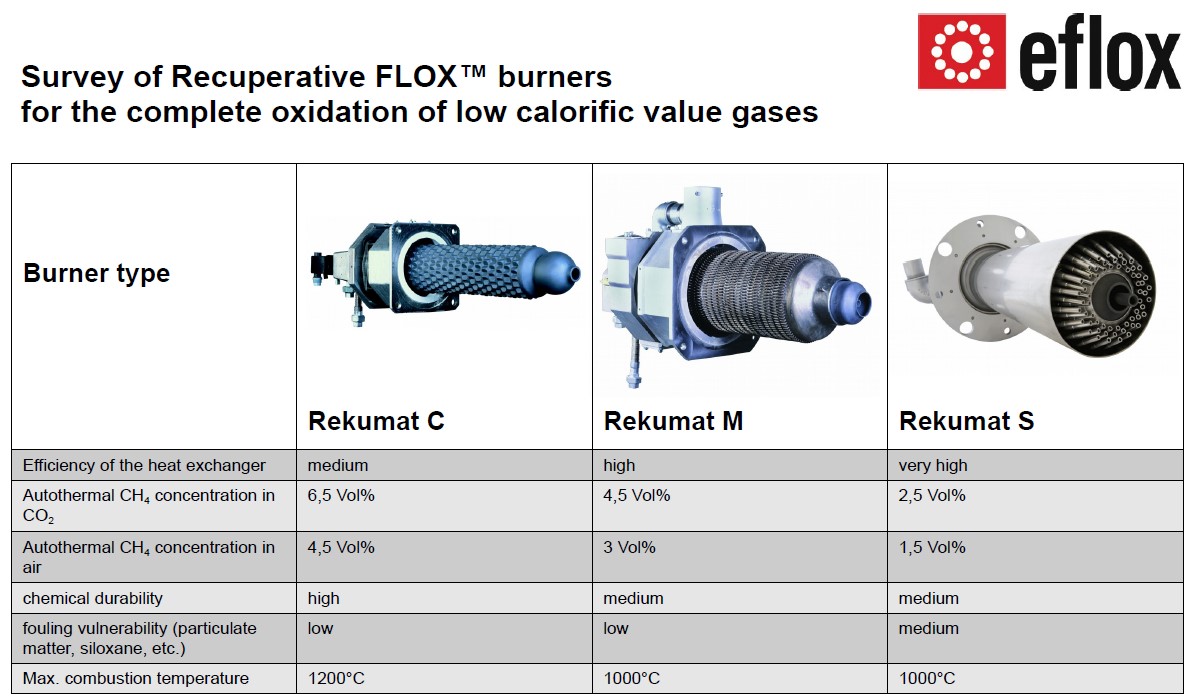

Depending on the type of gas upgrading the residual methan is part of the purg gas of the upgrading process. As methane has a high climate potential it must be oxidized before being emitted to the atmosphere. Otherwise it would deteriorate the climate impact of the biogas upgrading process. e-flox developed tailor made plants to oxidize these gases, which are primarily used in combination with PSA (pressure swing absorption) and membrane type gas upgrading systems. Combustion air and purge gas is preheated with flue gas heat prior to their injection into the combustion chamber. Depending on the type of preheater different autothermal methane concentrations can be reached. The operating point is the minimum methane concentration in the purge gas which can be burned without supplementary gas. Besides the methane concentration other hazardeous constituents like H2S or siloxanes influence the choice of burners to be used. In the download section a document shows a comparison of different burner types and their performance.

The flue gas downstream of the preheaters is still hot. Depending on the methane concentration and the burner type temperatures of 250-800°C are achieved. This flue gas can be used to produce warm water. The efficiency of such a waste heat recovery lies typically between 60 and 85%.

Even though we have developed standardized plants each plant has to be tailored individually to the customer's requirements respectively the individual type of gas treatment. Please contact us to receive an individually customized quotation.